by Bob Ashley Photographs by Jeff Schied

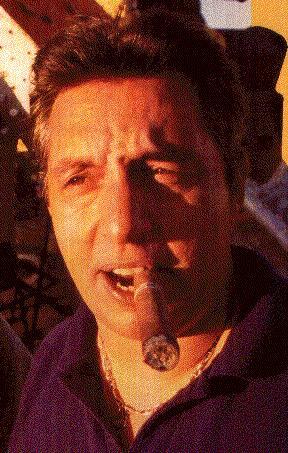

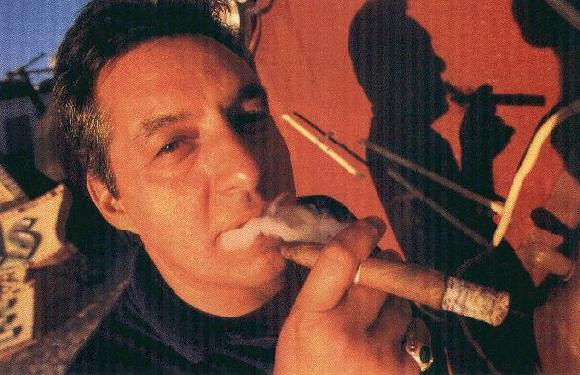

It's the end of May, but Rich Galdieri, owner of Las Vegas Cigar Company, is as happy as a kid at Christmas. A pair of custom-made boots -- horned alligator with calfskin uppers emblazoned with a color inlay of Las Vegas Cigar's red, white, and black "Diceman" logo -- have just been delivered by Tony Murga, a bootmaker from California whose in town for a few days.

Almost reverently, Galdieri removes the boots from their box, unable to contain his delight. "They're beautiful. Look at that leather. Have you ever seen anything like that?" Always the promoter, Galdieri wonders aloud, "Should I put them in the window?" "No," he says, answering himself, "They'd be gone in a minute. Maybe in the front case, next to a box of cigars. No, I'm going to wear them. Does anybody have a camera? I want to get a picture with Tony."

With the cigar business booming these days, almost anyone with an interest in cigars would love to be in Galdieri's boots. His domain is a small rolling factory and cigar store in a retail mall on the infamous Las Vegas strip -- formally known as Las Vegas Boulevard. Nearby are the towering casinos, offering the around-the-clock action that goes on that's made Las Vegas an icon.

Las Vegas Cigar Company makes and sells its own brand of cigars, using tobacco imported from the Caribbean and Central America. Having started with one Cuban cigar maker seven years ago. Galdieri today employs a total staff of 24, including four Cuban and 10 Dominican cigar-rollers.

This year's production estimate is more than 800,000 hand-rolled cigars, nearly 50% of which will be sold via mail order to tourists who originally strolled by the store, or were referred by friends who did. That's not a lot of production by the standards of factories in Honduras or the Dominican Republic, which can produce tens of millions of hand-rolled cigars annually. But for Galdieri, the output is just about right -- small enough so that he can personally control quality, large enough so that he can order quantities of tobacco a year in advance.

"What I have here would only work in a tourist area like Las Vegas," Galdieri says, "If I opened this same store in L.A. or Chicago, it would be a neighborhood cigar store, where I could probably make a living. But once people walk through my door here, it begins to snowball. Most of my business comes in by word-of-mouth."

It's the end of May, but Rich Galdieri, owner of Las Vegas Cigar Company, is as happy as a kid at Christmas. A pair of custom-made boots -- horned alligator with calfskin uppers emblazoned with a color inlay of Las Vegas Cigar's red, white, and black "Diceman" logo -- have just been delivered by Tony Murga, a bootmaker from California whose in town for a few days.

Almost reverently, Galdieri removes the boots from their box, unable to contain his delight. "They're beautiful. Look at that leather. Have you ever seen anything like that?" Always the promoter, Galdieri wonders aloud, "Should I put them in the window?" "No," he says, answering himself, "They'd be gone in a minute. Maybe in the front case, next to a box of cigars. No, I'm going to wear them. Does anybody have a camera? I want to get a picture with Tony."

With the cigar business booming these days, almost anyone with an interest in cigars would love to be in Galdieri's boots. His domain is a small rolling factory and cigar store in a retail mall on the infamous Las Vegas strip -- formally known as Las Vegas Boulevard. Nearby are the towering casinos, offering the around-the-clock action that goes on that's made Las Vegas an icon.

Las Vegas Cigar Company makes and sells its own brand of cigars, using tobacco imported from the Caribbean and Central America. Having started with one Cuban cigar maker seven years ago. Galdieri today employs a total staff of 24, including four Cuban and 10 Dominican cigar-rollers.

This year's production estimate is more than 800,000 hand-rolled cigars, nearly 50% of which will be sold via mail order to tourists who originally strolled by the store, or were referred by friends who did. That's not a lot of production by the standards of factories in Honduras or the Dominican Republic, which can produce tens of millions of hand-rolled cigars annually. But for Galdieri, the output is just about right -- small enough so that he can personally control quality, large enough so that he can order quantities of tobacco a year in advance.

"What I have here would only work in a tourist area like Las Vegas," Galdieri says, "If I opened this same store in L.A. or Chicago, it would be a neighborhood cigar store, where I could probably make a living. But once people walk through my door here, it begins to snowball. Most of my business comes in by word-of-mouth."

Galdieri, 53, got into the cigar business in 1989 after owning a ceramic dental lab in a New Jersey suburb of New York for twenty years. "It was a time to make a change in my life," Galdieri says, "I picked Vegas because I like the heat and I have some friends and relatives here. I came out here with the intention of semi-retiring, but I got caught in a jackpot. I took a job in the Holiday Inn selling time-shares. I worked one day, and I quit. It was too high-pressure and that's not my style."

"I ended up going into a venture selling air conditioners with a guy. I went broke. Then I started selling solar screens door-to-door," he continues.

"A Cuban friend suggested I get into the cigar business. He told me that the cigar business is a sleeping giant. I scraped together enough cash to hire one cigar maker and open a small store near Bally's. At the beginning, there was me, the roller, and a cash register. I'd leave him in the store during the day and I'd go sell solar screens."

At first, Galdieri made 10 different cigars, a number that has grown to 17 today. "I tried to establish a variety so we could hit every personality," Galdieri says.

The Las Vegas Cigar Co. blend is a mixture of tobaccos from the Dominican Republic, Santo Domingo, and Mexico, with either a Mexican or Ecuadoran wrapper, depending on whether the cigar is, respectively, a maduro or natural. Establishing the blend was a hit-and-miss proposition. "We ordered tobacco from all over -- Mexico, Honduras, the DR -- and we just started putting blends together and smoking them," Galdieri says. "Some were too harsh, others too bitter or too bland. It took about a month of smoking different blends before we came up with the blend we have today.

"Number one the blend is not harsh on your throat, and, number two, it's got great aroma. It doesn't burn your nose, and the wrapper I use doesn't have the bitter aftertaste that a lot of cigars leave."

Galdieri has been a cigar smoker since he was 16. "I was always around cigars. I had five uncles who smoked them. I used to smoke Perlitos -- a sun-dried cigar from Brazil. Now, I mostly smoke my own brand, not because it's mine, but because I like the cigar."

Las Vegas Cigars range in size from the Nix, a 5" x 30 ring gauge long-filler named for Galdiere's 12-year-old son, Nick, to the mammoth 9" x 57 ring gauge El Rey. Single cigars at box prices range from $1.30 each for a Nix, to $6.19 for an El Rey.

The company also makes sweetened cigars in each size by applying a mixture of sugar and water to the wrapper after the cigar is made. "I've got customers who won't buy anything but sweets," Galdieri says. Noting that he drinks straight Cuban-style coffee that his rollers drink heavily sweetened, "I can't put a sweet cigar in my mouth. I almost gag." Galdieri says. Las Vegas Cigar also offers a cigar flavored with spiced rum.

"I ended up going into a venture selling air conditioners with a guy. I went broke. Then I started selling solar screens door-to-door," he continues.

"A Cuban friend suggested I get into the cigar business. He told me that the cigar business is a sleeping giant. I scraped together enough cash to hire one cigar maker and open a small store near Bally's. At the beginning, there was me, the roller, and a cash register. I'd leave him in the store during the day and I'd go sell solar screens."

At first, Galdieri made 10 different cigars, a number that has grown to 17 today. "I tried to establish a variety so we could hit every personality," Galdieri says.

The Las Vegas Cigar Co. blend is a mixture of tobaccos from the Dominican Republic, Santo Domingo, and Mexico, with either a Mexican or Ecuadoran wrapper, depending on whether the cigar is, respectively, a maduro or natural. Establishing the blend was a hit-and-miss proposition. "We ordered tobacco from all over -- Mexico, Honduras, the DR -- and we just started putting blends together and smoking them," Galdieri says. "Some were too harsh, others too bitter or too bland. It took about a month of smoking different blends before we came up with the blend we have today.

"Number one the blend is not harsh on your throat, and, number two, it's got great aroma. It doesn't burn your nose, and the wrapper I use doesn't have the bitter aftertaste that a lot of cigars leave."

Galdieri has been a cigar smoker since he was 16. "I was always around cigars. I had five uncles who smoked them. I used to smoke Perlitos -- a sun-dried cigar from Brazil. Now, I mostly smoke my own brand, not because it's mine, but because I like the cigar."

Las Vegas Cigars range in size from the Nix, a 5" x 30 ring gauge long-filler named for Galdiere's 12-year-old son, Nick, to the mammoth 9" x 57 ring gauge El Rey. Single cigars at box prices range from $1.30 each for a Nix, to $6.19 for an El Rey.

The company also makes sweetened cigars in each size by applying a mixture of sugar and water to the wrapper after the cigar is made. "I've got customers who won't buy anything but sweets," Galdieri says. Noting that he drinks straight Cuban-style coffee that his rollers drink heavily sweetened, "I can't put a sweet cigar in my mouth. I almost gag." Galdieri says. Las Vegas Cigar also offers a cigar flavored with spiced rum.

Galdieri sells only his cigars, figuring that adding other brands to his humidor would create competition with his own brand. "I'm in control here. I know what my rollers are doing and I can control the quality."

Across the street from the Las Vegas Cigar Co. store is the Monte Carlo Hotel and Casino which opened in June; a block to the south is the MGM Grand Hotel. A little farther south on the other side of the boulevard is Las Vegas' most ambitious effort yet -- a hotel casino dubbed New York, New York, the exterior of which is a reproduction of the Manhattan skyline.

The enthusiasm that Galdieri displayed about his new boots is emblematic of his relationship with his customers. Whenever they stop in, a greeting is always extended along with an invitation to linger in the well-stocked walk-in humidor.

"Whenever I walk into a store ready to spend my money, I want to be greeted," Galdieri says. "I make sure we do that here. A greeting and a smile breaks the ice." Galdieri's goal is to provide customers with inexpensive, yet high-quality, cigars. "I don't go for the high dollars," Galdieri says. "I want to give people a good cigar at a good price."

A five-and-a-half-foot cigar store Indian in muted yellow, red, blue and green beckons customers from the factory's front window. Ceiling fans turn slowly to keep the extremely dry Las Vegas air in motion inside the store. "It's difficult to make cigars here because of the low humidity," Galdieri says. "You have to be careful with the tobacco. you have to make sure it's humidified properly."

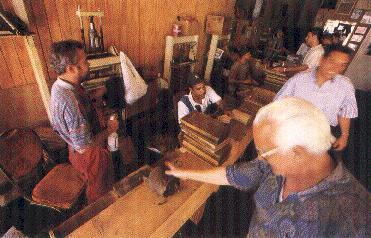

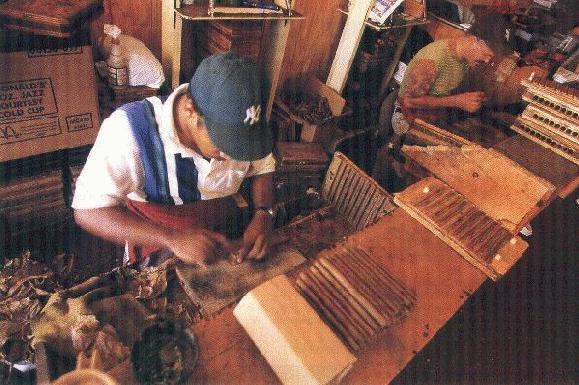

The store has six rolling stations arranged in two aisles that extend from the front door. People walking by are invited into the store to watch the rollers by a door that remains open even in 100 degree+ temperatures. Tobacco that is to be used by the rollers is given to them each morning in a white plastic bag. The morning is spent bunching the tobacco and placing into molds that are then put into presses to establish the cigar's shape. The afternoon is set aside for adding the wrapper after the cigars have been taken out of the presses. The rollers work earnestly at their benches, first choosing the tobacco that will go into an individual cigar and then individually testing the leaf by holding it to their noses and inhaling deeply.

Across the street from the Las Vegas Cigar Co. store is the Monte Carlo Hotel and Casino which opened in June; a block to the south is the MGM Grand Hotel. A little farther south on the other side of the boulevard is Las Vegas' most ambitious effort yet -- a hotel casino dubbed New York, New York, the exterior of which is a reproduction of the Manhattan skyline.

The enthusiasm that Galdieri displayed about his new boots is emblematic of his relationship with his customers. Whenever they stop in, a greeting is always extended along with an invitation to linger in the well-stocked walk-in humidor.

"Whenever I walk into a store ready to spend my money, I want to be greeted," Galdieri says. "I make sure we do that here. A greeting and a smile breaks the ice." Galdieri's goal is to provide customers with inexpensive, yet high-quality, cigars. "I don't go for the high dollars," Galdieri says. "I want to give people a good cigar at a good price."

A five-and-a-half-foot cigar store Indian in muted yellow, red, blue and green beckons customers from the factory's front window. Ceiling fans turn slowly to keep the extremely dry Las Vegas air in motion inside the store. "It's difficult to make cigars here because of the low humidity," Galdieri says. "You have to be careful with the tobacco. you have to make sure it's humidified properly."

The store has six rolling stations arranged in two aisles that extend from the front door. People walking by are invited into the store to watch the rollers by a door that remains open even in 100 degree+ temperatures. Tobacco that is to be used by the rollers is given to them each morning in a white plastic bag. The morning is spent bunching the tobacco and placing into molds that are then put into presses to establish the cigar's shape. The afternoon is set aside for adding the wrapper after the cigars have been taken out of the presses. The rollers work earnestly at their benches, first choosing the tobacco that will go into an individual cigar and then individually testing the leaf by holding it to their noses and inhaling deeply.

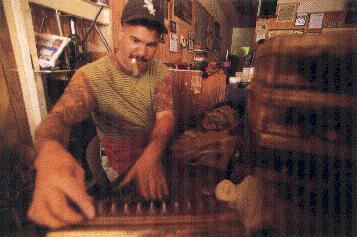

Typical of Las Vegas Cigar Co.'s rollers is Leonardo Rosario, a 35-year-old from the Dominican Republic began working in cigar factories at age seven. After working for 20 years -- primarily at a Matasa Factory -- he came to the United States eight years ago, and has been rolling cigars for Las Vegas Cigar Co. for the past two years.

The only difference, Rosario says, between rolling cigars in the Dominican Republic and at Las Vegas Cigar Co. is that "here, the money is better." Like most of Galdieri's rollers, Rosario learned about Las Vegas Cigar Co. from a friend who also rolled cigars. Four of Galdieri's rollers are from the same family -- three brothers and their father.

Rosario prefers to make Las Vegas Cigar Co.'s Montefino and Punch sizes, both of which are rolled to a 52 ring gauge. "That's the most comfortable size to work with," he says. Rosario also doesn't hesitate to label Las Vegas Cigar Co's blend as superior. "The best cigar I've ever smoked has come out of this factory," Rosario says. "I've smoked different cigars all my life. the blend here is very desirable to me."

Partly that is because of the experience of Galdieri's employees. The factory's production manager, Rene Montejo, worked 24 years at the H. Upmann factory in Cuba before coming to the United States. Montejo primary job is to see that rollers are consistent, both in the tobacco they choose for each cigar and in the construction of the cigar itself.

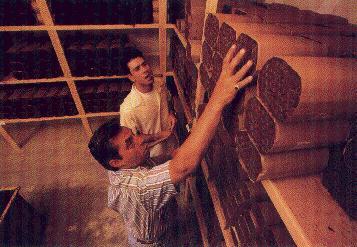

The rollers arrive each morning at 7 A.M. Their daily production -- 150 to 300 cigars each -- is gathered in bundles of 50 cigars wrapped in plain brown paper, dated, and signed by the roller. The bundles are then transported to Galdieri's warehouse near the Las Vegas airport where they are aged a minimum of 30 to 60 days. Each day, bundles that have matured long enough to be sold are brought to the store where they are either used to stock humidor bins for single sales or packed in cardboard boxes.

Galdieri keeps a stock of between 120,000 and 150,000 cigars in the warehouse most of the time. "I like to keep a stock that will last between 60 and 90 days. Churchills move fast, and so do our Punch and Corona Largo sizes. I try to keep 2,000 to 3,000 Nix in inventory. With Churchills, I want to be ahead at least 20,000 so that I can age them." The store carries a small selection of medium-priced humidors, carry cases, and pipes. Galdieri doesn't sell cigarettes. to augment its mail order business, Las Vegas Cigar Co. maintains a Web page (http://www.lvcc.com).

The only difference, Rosario says, between rolling cigars in the Dominican Republic and at Las Vegas Cigar Co. is that "here, the money is better." Like most of Galdieri's rollers, Rosario learned about Las Vegas Cigar Co. from a friend who also rolled cigars. Four of Galdieri's rollers are from the same family -- three brothers and their father.

Rosario prefers to make Las Vegas Cigar Co.'s Montefino and Punch sizes, both of which are rolled to a 52 ring gauge. "That's the most comfortable size to work with," he says. Rosario also doesn't hesitate to label Las Vegas Cigar Co's blend as superior. "The best cigar I've ever smoked has come out of this factory," Rosario says. "I've smoked different cigars all my life. the blend here is very desirable to me."

Partly that is because of the experience of Galdieri's employees. The factory's production manager, Rene Montejo, worked 24 years at the H. Upmann factory in Cuba before coming to the United States. Montejo primary job is to see that rollers are consistent, both in the tobacco they choose for each cigar and in the construction of the cigar itself.

The rollers arrive each morning at 7 A.M. Their daily production -- 150 to 300 cigars each -- is gathered in bundles of 50 cigars wrapped in plain brown paper, dated, and signed by the roller. The bundles are then transported to Galdieri's warehouse near the Las Vegas airport where they are aged a minimum of 30 to 60 days. Each day, bundles that have matured long enough to be sold are brought to the store where they are either used to stock humidor bins for single sales or packed in cardboard boxes.

Galdieri keeps a stock of between 120,000 and 150,000 cigars in the warehouse most of the time. "I like to keep a stock that will last between 60 and 90 days. Churchills move fast, and so do our Punch and Corona Largo sizes. I try to keep 2,000 to 3,000 Nix in inventory. With Churchills, I want to be ahead at least 20,000 so that I can age them." The store carries a small selection of medium-priced humidors, carry cases, and pipes. Galdieri doesn't sell cigarettes. to augment its mail order business, Las Vegas Cigar Co. maintains a Web page (http://www.lvcc.com).

Galdieri stores bulk tobacco at the warehouse where eight other rolling stations are set up. Although the warehouse is only three months old, it already is crowded with the inventory of aging cigars and bulk tobacco, which Galdieri receives two-to-four ton orders. Tobacco being rolled this year was harvested at least one year ago.

Because a majority of his customers are out-of-town visitors to the Las Vegas strip, Galdieri's mail-order business is burgeoning. "I have shipped to just about every country in the world except China," Galdieri says. He also provides cigars wholesale to a handful of stores in the United States. He occasionally supplies cigars for dinners and private parties at local casinos, but doesn't emphasize that part of the business because of the hassles involved. Although mail order accounts for 50% of his business, Galdieri says, "Without these doors being open, I wouldn't have that."

Until recently Galdieri purchased his tobacco from a broker in Miami. In order to keep costs low during the summer of 1995 Galdieri began to explore importing directly from tobacco plantations in the Dominican Republic. Just like many cigar smokers, however, Galdieri has to deal with the popularity of cigars and the pressure that puts on tobacco supplies. After a recent shortage of Dominican binder, Galdieri can be heard on the telephone negotiating with a grower in the Dominican Republic for an emergency shipment of tobacco.

While the company strives for a consistent taste for its cigars, Galdieri says the formula varies depending on a given crop. "You can't control the way a crop shows up. Nature is the biggest beast in the world. There are lots of variables that growers can't control -- the amount of rain, the temperature, whether there's a lot of sunshine or very little. They all effect the tobacco. The formula of the blend changes depending on the strength of the tobacco harvest."

Because a majority of his customers are out-of-town visitors to the Las Vegas strip, Galdieri's mail-order business is burgeoning. "I have shipped to just about every country in the world except China," Galdieri says. He also provides cigars wholesale to a handful of stores in the United States. He occasionally supplies cigars for dinners and private parties at local casinos, but doesn't emphasize that part of the business because of the hassles involved. Although mail order accounts for 50% of his business, Galdieri says, "Without these doors being open, I wouldn't have that."

Until recently Galdieri purchased his tobacco from a broker in Miami. In order to keep costs low during the summer of 1995 Galdieri began to explore importing directly from tobacco plantations in the Dominican Republic. Just like many cigar smokers, however, Galdieri has to deal with the popularity of cigars and the pressure that puts on tobacco supplies. After a recent shortage of Dominican binder, Galdieri can be heard on the telephone negotiating with a grower in the Dominican Republic for an emergency shipment of tobacco.

While the company strives for a consistent taste for its cigars, Galdieri says the formula varies depending on a given crop. "You can't control the way a crop shows up. Nature is the biggest beast in the world. There are lots of variables that growers can't control -- the amount of rain, the temperature, whether there's a lot of sunshine or very little. They all effect the tobacco. The formula of the blend changes depending on the strength of the tobacco harvest."

One of the more difficult aspects of the cigar-making business, Galdieri says, is holding on to employees who know how to roll the cigars he wants made. Rollers at Las Vegas Cigar are paid for each cigar they make. Although Galdieri has set production goals, there are no quotas.

To encourage his rollers to remain with the company, Galdieri has set up a 401(k)-type plan where he matches 50 cents on the dollar, up to $100 in earnings per week, if the roller puts the money into a savings account. "They've each signed a four-year contract," Galdieri says, "If they leave before the end of four years or if they want their money early, they get their money minus the money I've put in. If they stay four years, they get their money and they get my money."

Although Galdieri is continually being asked whether he can supply Cuban cigars to his customers, his answer always is a firm "no." Besides, he says, Cuban cigars aren't what they once were. "Before Castro, there's no doubt that Cuba made the best cigars. But the big growers, the guys who knew how to make the best cigars, were forced to leave the country. What you have now in Cuba are second-rate growers and second-rate rollers. The quality has definitely gone down."

"There are Cubans in the United States who are cleaning floors who are great cigar makers, but it's difficult to find them because it's such a small group of people. Being a world-class cigar maker is like the difference between a cook and a chef. They both prepare food, but a chef's product will be better."

To carry the analogy to Las Vegas Cigar Co. -- any competent roller can make a stogie. Here, they make cigars.

Smoke Magazine Archives